Anker Stuy Partners with Trivec Eco UK

Advanced Paint Disposal & Water Treatment for the UK Joinery Sector

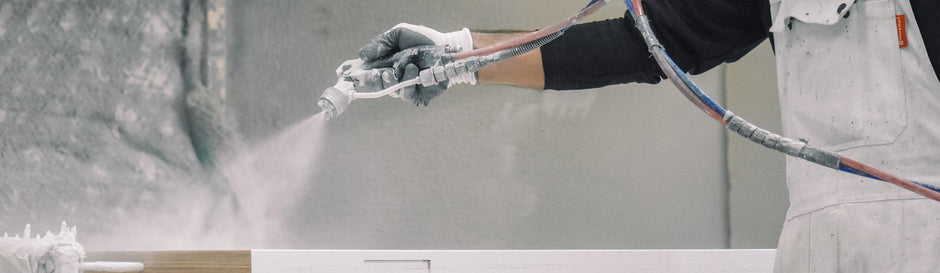

At Anker Stuy Coatings, innovation and sustainability guide everything we do. This week we had the pleasure of hosting Trivec Eco UK at our site to formalise a new partnership. Together, we will bring to the UK joinery and coatings sectors an advanced paint disposal and water treatment system that transforms how workshops manage waste paint.

In this blog, we explain why this matters, how the system works, and how it can benefit your workshop: financially, operationally, and environmentally.

The Challenge: Managing Waste Paint in Joinery Operations

Many joinery workshops and spray shops struggle with disposing of leftover paint and rinse water. Traditional approaches typically involve:

- Storing waste paint in IBCs, cans or drums

- Arranging hazardous waste collection and disposal contracts

- Discharging rinse water (if allowed), which can cause environmental risk or regulatory issues

Disposing of waste paint is not only expensive, but also has environmental consequences. Pouring paint into drains can lead to blockages, damage to treatment systems, and contamination of water supplies.

To offer a practical, sustainable alternative that reduces costs, reduces the burden on waste contractors, and helps workshops stay compliant and green.

About Trivec Eco: Expertise in Rinse-Water Treatment & Recycling

Trivec Eco UK specialises in paint waste water recycling and disposal systems for industrial and workshop settings. Their solutions are engineered to treat water from cleaning operations so that:

Solid Separation

Paint particles are separated from water

Water Recovery

Clean water is recovered and reused

Minimal Discharge

Environmental discharge is minimised or eliminated

One of their flagship systems is the Trivec AS120 wastewater system (120 L), designed to purify rinse water from water-based coatings, lacquers, stains and adhesives.

These systems typically use flocculation, filtration and separation to turn paint-laden water into discrete solid waste (paint sludge) and return clean water for reuse. This aligns precisely with Anker Stuy's commitment to sustainable finish solutions.

How the System Works — Simple 5-Step Process

The Trivec waste paint disposal system cleans and reuses water while converting waste paint into a manageable solid — making your finishing process cleaner, safer, and more efficient.

Collect & Mix Waste Paint

Leftover paint and rinse water are collected together in the Trivec unit — no sorting required.

Add Treatment Agent

A flocculation agent is added, binding paint particles into larger clusters for easy separation.

Separate Solids from Water

The system filters out the paint solids from the liquid, leaving clarified water below.

Form Solid Waste Block

The separated paint solids dry into a compact "sludge cake" that's easy and safe to dispose of.

Recover & Reuse Clean Water

The clean water is stored for reuse in cleaning or rinsing operations — reducing water consumption and costs.

Waste paint becomes a dry, manageable solid — and your rinse water gets recycled for reuse, saving money and reducing your environmental footprint.

Key Benefits for Joinery Workshops

This partnership delivers value across multiple dimensions:

Significant Cost Savings

Disposing of paint-laden rinse water through traditional hazardous waste contractors typically costs around £1.00–£1.50 per litre. For a workshop generating 5,000 litres, this means £5,000–£7,500 in annual disposal costs.

With a Trivec system, that same volume can be treated on-site for as little as £0.30 per litre — a potential saving of up to 80–85% on disposal costs. These savings quickly offset the investment in the unit and continue to deliver value over time.

Time Saved

Less handling and fewer logistics associated with waste paint

Environmental Compliance

Less risk of non-compliant discharge or accidental release

Circular Use

Recycled rinse water reduces fresh water consumption

Cleaner Workflows

Less clutter, simpler waste handling

In addition, integrating such a system aligns with sustainability goals and can be a positive differentiation for workshops committed to greener practices.

Anker Stuy's Role & On-Site Support

At Anker Stuy, we don't just supply coatings — we support performance, process, and outcomes. As part of this partnership:

- Demonstrations and technical support to help you integrate the disposal system

- On-site audits to assess how the system fits into your current spray shop layout and workflow

- Installation, operation, and maintenance guidance to ensure smooth adoption

This aligns with Anker Stuy's broader approach of combining product excellence with on-site service and knowledge sharing.

Case Use & System Options

Depending on the size of your operation, Trivec offers different capacities and systems. For example, their AS120 (120 L) is suited to small to medium workshops. Larger facilities might opt for more scale or modular systems.

Additionally, the system is engineered for waterborne coatings (the kind widely used in modern joinery finishing). Trivec's technology is suitable for rinsing water from water-based coatings, lacquers, adhesives and stains.

We are currently arranging pilot installs and client rollouts. If you'd like to see the system in action, we'd be happy to visit your workshop and provide a tailored proposal.

Next Steps

Are you a joinery workshop or finishing facility looking to reduce waste costs and improve sustainability? Here's how to move forward:

How to Get Started

- Contact us to request a free consultation or demonstration

- Book an on-site audit — we'll assess your waste streams, workflow and facility

- Select the appropriate Trivec disposal unit

- Work with our technical team to install, train, and integrate

By combining Anker Stuy's coating expertise with Trivec's disposal technology, we can help you transform your waste paint challenge into a cleaner, greener, cost-efficient process.

Let's work together to raise the standard for sustainable finishing in the UK joinery sector.